Regular maintenance and lubrication at production facilities guarantees a long-lasting chain. Chain lubrication is often time consuming, and production needs to be halted during the process. FB Ketju offers a lubrication system that operates automatically after installation and monitors oil consumption simultaneously.

FB Group’s RotaLube® lubrication system is manufactured in the United Kingdom. It is a automated and unique system for applying lubricants.

Lubrication applied exactly on the right place on the chain

RotaLube® is a simple and efficient solution for extending the lifespan of chains of all sizes. Precise lubrication reduces environmental contamination, lubricant consumption, power consumption and production downtime. Lubrication minimizes the speed of chain wear, corrosion and noise, among other things. Conveyor chains in certain industries require specialized lubricants to prevent product contamination and spoilage.

Lubrication systems are used in many different industries, such as wood, packaging and food industries. RotaLube® complements FB Ketju’s single supplier model. The model ensures that the customer receives everything they need for their chains from one place. The purpose of the model is to offer the customers more comprehensive services than ever before – to save their time and effort.

Benefits of RotaLube® for customers and chains

- A precise solution for chain lubrication which allows for accurate and efficient application of lubrication in the right place without any wasted oil.

- The chain life is extended by reducing the wear.

- The system monitors oil consumption and sends a report to the customer when oil levels are too low.

- The automatic lubrication system replaces old traditional lubrication methods which reduces the costs and creates less waste.

- The customer gains ease and convenience for the lubrication process; production does not need to be stopped and no personnel is needed to complete the process.

- The system can easily be retrofitted on existing chains.

- The installation process can be designed for all individual spaces and needs.

- The lubrication sprocket can be added to almost any position on the line.

- RotaLube® system can be used to clean the chain with air pressure before lubrication is applied.

How is the lubricantion applied?

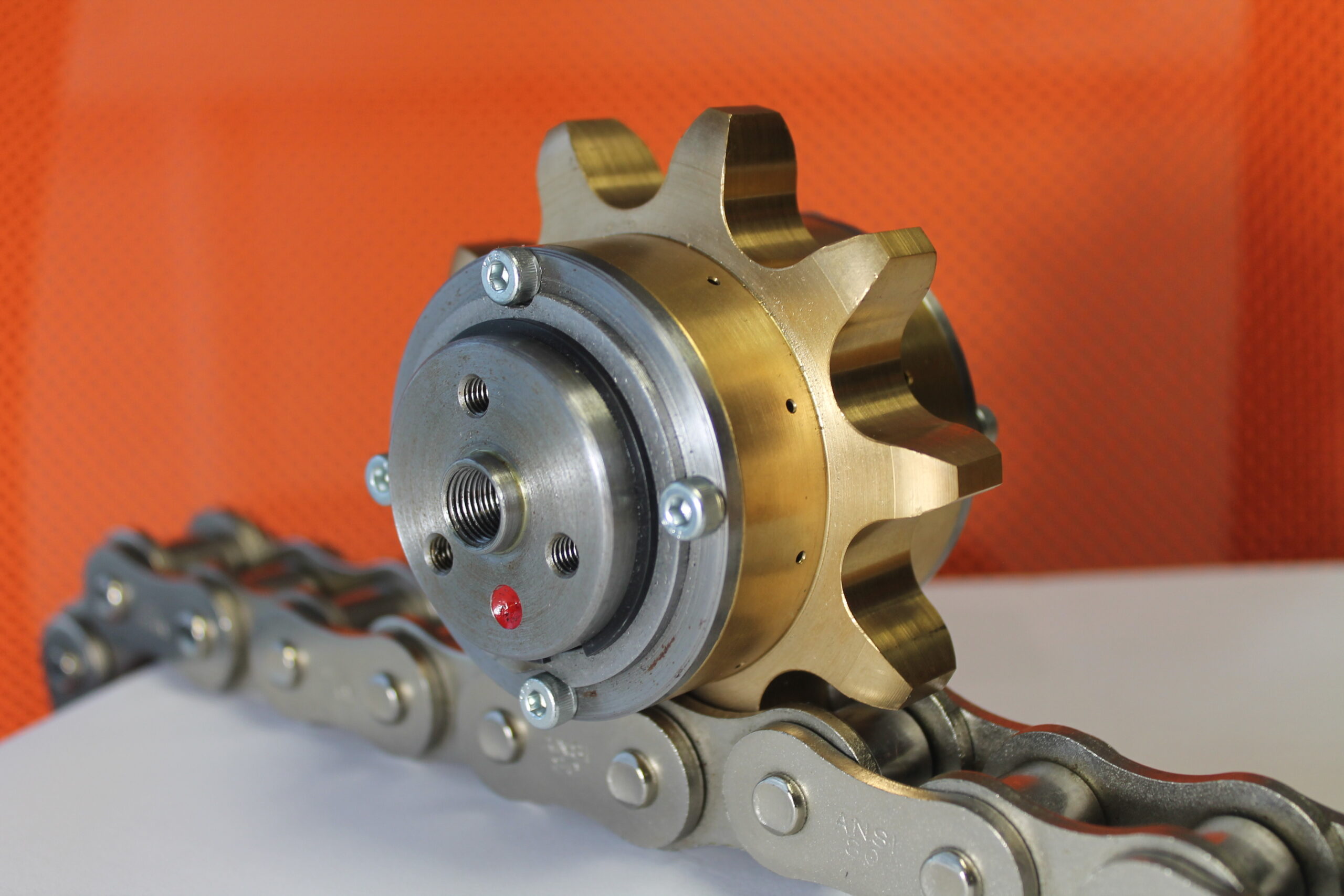

- A rotating ring gear with lubrication holes is added into the system. The lubrication holes are spaced evenly and fitted for each individual chain.

- When the lubrication hole on the sprocket is in the downwards position on top of the chain, oil is applied on the chain from the pressurised lubrication channels.

- The lubrication channels can be adjusted and closed off completely if necessary.

- One sprocket per chain is enough, but several sprockets can be installed on a chain according to the customer’s needs.

- Oil pipes can be connected to the sprocket on both sides or just one side.

- A roughly 200-litre barrel is included with the lubrication system. This guarantees that the oil will not run out.

Selection

The operational conditions, environment and purpose of the chain have an impact on the right choice of lubricant. All RotaLube® lubrication systems come with different features depending on the weight of the transported goods, temperature of the environment, dust, water, and whether the production facility handles acids or alkaline substances, for example.